| serial number and name | Cabinet model contents |

|

Cabinet 1, the composition and characteristics of the machine |

Single-cylinder internal combustion engine, jaw crusher, sewing machine, kinematic p*r (5 pieces) |

|

Cabinet 2, plane linkage mechanism |

Five-bar hinge mechanism, crank slider mechanism, hinged four-bar mechanism, large screen mechanism, pole angle of crank rocker mechanism, mixer, inertial screen mechanism, rolling stock mechanism , crane, rotating guide rod mechanism, crank rocker Block mechanism, crank moving guide rod mechanism, double rotating block mechanism, double slider mechanism, mechanism with emergency return characteristics, clamping mechanism |

|

Cabinet 3, cam mechanism |

Internal combustion engine valve mechanism, prototype turning mechanism, automatic feeding mechanism, indexing indexing mechanism, cams with different locking methods w, cams with different locking methods b, cams with different locking methods c, cams with different locking methods e. Cams f with different locking methods |

|

Cabinet 4, intermittent motion mechanism |

Rectangular tooth two-way ratchet mechanism, ratchet mechanism, hook double-action pawl, str*ght double-action pawl, sheave mechanism, spatial sheave mechanism, sheave mechanism on hexagonal lathe, incomplete external meshing gear mechanism, internal Incomplete meshing gear mechanism, cam intermittent motion mechanism |

|

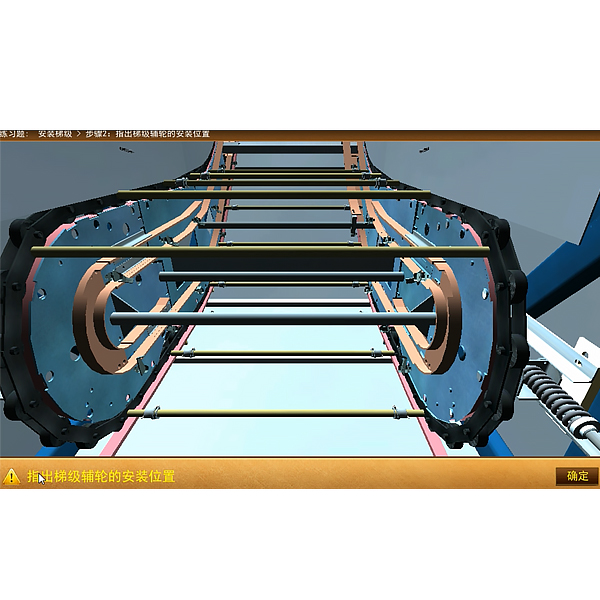

Cabinet 5, belt drive |

Timing belt, tensioning pulley device a, tensioning pulley device b, belt periodic tensioning device (slide type), belt periodic tensioning device (swing frame type), automatic belt tensioning device, V-pulley Structure (4 pieces) |

|

Cabinet 6, ch*n drive |

Ch*n drive, toothed ch*n, double row roller ch*n, roller ch*n, roller link joint type (3 pieces), sprocket structure, ch*n drive tensioning (2 pieces) |

|

Cabinet 7, gear transmission |

Internal ring gear transmission, rack and pinion transmission, bevel gear transmission , hyperbolic bevel gear transmission, helical bevel gear transmission, helical gear transmission, helical gear and rack transmission, worm gear transmission, cambered worm gear transmission, spur gear transmission, Helical gear transmission, herringbone gear transmission |

|

Cabinet 8, basic properties of gears |

Names of each part of the gear (3 items), pressure angle of the helical rack, formation of involute, tooth breakage a, b, tooth surface pitting, tooth surface gluing, tooth surface wear, involute surface formation (2 items) ), force analysis of helical cylindrical gears, force analysis of bevel gears, gear shaft (2 pieces), web type bevel gears, cast spoke type cylindrical gears, profiling cut gears, generation cut gears |

|

Cabinet 9, gear system |

Fixed axis gear tr*n (2 pieces), plane planetary gear tr*n a, b, space planetary gear tr*n, variable direction gear tr*n, automobile rear axle differential, cycloidal pinwheel transmission mechanism, harmonic gear transmission, reducer , gear tr*n in planetary reducer |

|

Cabinet 10, other commonly used parts and components |

Sleeve couplings, flange couplings, multi-plate friction clutches, gear couplings, elastic sleeve pin couplings, elastic pin couplings, double universal couplings, tooth-type safety clutches , roller overrunning clutch, leaf spring |

|

Cabinet 11, threaded connections and screw drives |

Thread profile (triangular, rectangular, trapezoidal, zigzag), thread direction (left-hand, right-hand), thread number, pitch and lead (one-way right-hand, double-line left-hand), bolt connection, double thread Head bolt connection, screw connection, set screw connection (a, b), spring washer, tilt nut, nylon ring lock nut, channel nut and cotter pin, finned washer for round nut, flexible bolt (2 pieces) , stop washer, anti-loosening by punching point method, anti-loosening by adhesive method, permanent anti-loosening, series wire connection, use load-reducing pin, use load-reducing sleeve, use load-reducing key, bolts bear eccentric load (a, b , c), application of boss countersunk head seat (a, b), application of inclined plane washer, bolt group connection subject to lateral load, improvement of load distribution between thread teeth (a), elastic element under nut, metal gasket and Sealing ring seal (a, b), screw jack, machine tool rest feeding mechanism, intubated external circulation rolling screw |

|

Cabinet 12, shaft and hub connection |

Transmission shaft, optical shaft, stepped shaft, hollow shaft, crankshaft, round nut positioning, ret*ning ring fixation, firm screw fixation, pressure plate shaft end fixation device, flat key connection, guide flat key connection, feather key connection, wedge key connection, Tangential key connection, semi-circular key connection, spline connection (3 pieces), common methods of axial fixation of the inner ring (4 pieces), axial locking method of the outer ring (8 pieces), fully solid support, fixed-swing type Supports, integral radial sliding bearings, split radial sliding bearings, oil holes, oil grooves (3 pieces), disassembly of bearing inner rings, cold press installation of bearings, types of rolling elements (6 pieces), integral gears (2 pieces) |

|

Cabinet 13, bearing |

Types of rolling elements, spherical ball bearings, spherical roller bearings, tapered roller bearings, thrust ball bearings, deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, bearing diameter series, inner ring axial fixation There are 4 commonly used methods, 8 axial locking methods of the outer ring, fully fixed support, fixed-swivel support, integral radial sliding bearing, partial radial sliding bearing, oil hole, and oil groove. |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap