| serial number | Device name | specification | unit | quantity | Remark |

| (one) | Absorption and desorption tr*ning device objects: | set | 1 | ||

| 1 | Frame\st*rs\guardr*ls: | Frame\st*rs\guardr*l: length*width*height is about 3700*2000*3400. The m*n frame of the upper and lower platforms uses 8# channel steel, the auxiliary frame uses 4# angle steel, and the installation pillars use Φ89*3 steel pipes. The platform board uses δ3 lentil-shaped pattern board. The st*rs are placed on the left side of the frame. The st*r frame has a total of 4# angle steel, and the st*r slab is made of δ3 lentil-shaped pattern plate. The guardr*l vertical installation columns use 30×30×δ1.5 square steel pipes, and the horizontal pipes use Φ25*δ1.5 steel pipes. | set | 1 | |

| 2 | Desorbent storage tank | Desorbent storage tank: Φ350*600, st*nless steel, normal temperature and pressure. | tower | 2 | |

| 3 | Desorption gas buffer tank | Desorption gas buffer tank: Φ300*400, st*nless steel, normal temperature and pressure. | tower | 1 | |

| 4 | CO2 dryer | CO2 dryer: φ106, height 180, filter element 5 microns. | tower | 3 | |

| 5 | Packed absorption tower | The m*n body is made of hard glass φ120×10-1300 mm; the upper outlet section is made of 304 st*nless steel φ120×300 mm; the lower inlet section is made of 304 st*nless steel φ100×50 mm; the filler is high-efficiency regular filler; with industrial effusion ring and liquid distributor. Install a liquid redistributor. | set | 1 | |

| 6 | Packed desorption tower | Desorption tower: M*n body of high borosilicate glass φ120×10-1300mm; upper outlet section, st*nless steel φ120×300mm; lower inlet section, st*nless steel φ100-50mm; packing is high-efficiency regular packing, with industrial liquid ring and liquid distributor. | set | 1 | |

| 7 | Absorption tower enhanced *r pump | Absorption tower enhanced *r pump, 380V, maximum flow rate 50m3/h, high efficiency and low noise vortex *r pump. | tower | 1 | |

| 8 | Absorption tower *r pump | Absorption tower *r pump, 220V, 450L/min, electromagnetic *r pump. | tower | 1 | |

| 9 | Desorption tower desorption *r pump | Desorption tower desorption *r pump, 380V, maximum flow rate 140m3/h, high efficiency and low noise vortex *r pump. | tower | 1 | |

| 10 | Absorption and desorption liquid pump | Absorption and desorption liquid pump: centrifugal pump, 380V, 1.2-4.8m³/h. Import DN32, export DN25. | tower | 2 | |

| 11 | fastener | Fasteners: cooperate with flanges, valves, frames, st*rs, guardr*ls, and brackets. The flange valve mounting screws use corresponding carbon steel screws, and the frame, guardr*l, and bracket mounting screws use corresponding galvanized screws. | set | 1 | |

| 12 | Flanges, valves, pipelines: | Flange: Matched with the corresponding equipment bracket, 1 set made of st*nless steel; Valve: 1 set matched with the equipment and pipeline; Pipeline: Matched with the equipment, made of 304 st*nless steel. | set | 1 | |

| (two) | Absorption and desorption tr*ning device sensor : | set | 1 | ||

| 1 | CO2 concentration sensor | CO2 concentration sensor: 0-20%, DC24V power supply, 4~20mA output. | tower | 2 | |

| 2 | CO2 concentration sensor |

CO2 concentration sensor: 0-4000PPM, DC24V power supply, 4-20mA output. , Accuracy: 40ppm+3% reading, Output: 4-20MA, Power supply: 24V, Signal: 4-20mA. |

tower | 1 | |

| 3 | Glass rotor flowmeter | Glass rotor flowmeter: LZB-25, 100-1000L/h, water, flange type. Accuracy level: 2.5. | tower | 2 | |

| 4 | Glass rotor flowmeter | Glass rotor flowmeter: LZB-10, 0.25-2.5m³/h, gas. Accuracy level: 2.5. | tower | 1 | |

| 5 | Glass rotor flowmeter | Glass rotor flowmeter: LZB-25, 1-10m³/h, gas, flange type. Accuracy level: 2.5. | tower | 1 | |

| 6 | Glass rotor flowmeter | Glass rotor flowmeter: LZB-4, 40-400L/h. Accuracy level: 2.5. | tower | 2 | |

| 7 | Orifice flow meter |

Orifice flow meter: Desorption tower inlet flow measurement, 1~10m3/h, st*nless steel, flange type. Material: st*nless steel, st*nless steel angle joint pressure taking (DN25-8); flange welding installation, st*nless steel; flange welding installation, nominal diameter (DN32mm); nominal pressure (PN1.6Mpa), working temperature (-50℃≤ t≤550℃); aperture ratio (0.10≤β≤0.75); Reynolds number range (5000≤ReD when 0.10≤β≤0.56, 10000≤ReD when (0.45≤β≤0.75); accuracy (level 2.0); Connection method (flange connection). |

tower | 1 | |

| 8 | Turbine flowmeter | Turbine flow meter: 0.2-1.2m³/h, 4~20mA output, water, st*nless steel. Accuracy: Level 1, medium temperature: -20℃~120℃; nominal pressure: 1.6Mpa; with protective inspection filter for easy m*ntenance. | set | 2 | |

| 9 | glass tube level gauge | Glass tube liquid level gauge: DN20/L650, flange type. | set | 2 | |

| 10 | glass tube level gauge | Glass tube liquid level gauge: DN20/L290, flange type. | set | 2 | |

| 11 | pressure gauge | Pressure gauge: Y100, 0-10Kpa, membrane box. Y100. | indivual | 3 | |

| 12 | Glass U-shaped differential pressure gauge | Glass U-shaped differential pressure gauge: 800 long. | indivual | 3 | |

| 13 | PT100 thermal resistance | PT100 thermal resistance: L=50, level 0.5, 0~100℃. Type 270. | indivual | 4 | |

| 14 | Differential pressure transmitter | Differential pressure transmitter: diffused silicon differential pressure transmitter, used in conjunction with orifice plate flowmeter. 0~2.5KPa, accuracy: ±1%, output signal: 4~20mA, power supply voltage: 16~35VDC wide range power supply, protection level: IP54, with clear button. | set | 1 | |

| (three) | Absorption and desorption tr*ning device control display instrument: | set | 1 | ||

| 1 | Temperature detection display instrument |

Temperature detection and display instrument: intelligent inspection instrument, 4 channels, 1~5V signal input, with touch buttons. Programmable modular inputs support a variety of thermocouple, RTD, voltage, current and two-wire transmitter inputs. Each channel can have different input specifications, and can independently define settings such as scale, decimal point position, display resolution, digital filter strength, and translation correction. Level 0.2 measurement accuracy. It can support up to 6 channels of signal measurement. It can be used as an analog data acquisition module in a computer monitoring system or PLC to provide analog data acquisition for the computer. It can also provide switching input or output to the host computer, and the host computer can perform switching operations through the instrument. . It has built-in calculation functions such as square root, multiplier, adder and subtractor, and can display and convert the calculation results into standard signal output or transmit them to the host computer. Built-in dry and wet bulb temperature measurement calculation function. Each circuit has independent upper and lower limit alarm functions, and its alarm output can be freely programmed, allowing multiple alarm signals to be output from the same module position. |

tower | 1 | |

| 2 | Concentration flow detection and display instrument |

Concentration flow detection and display instrument: intelligent inspection instrument, 4 channels, 1~5V signal input, with touch buttons. Programmable modular inputs support a variety of thermocouple, RTD, voltage, current and two-wire transmitter inputs. Each channel can have different input specifications, and can independently define settings such as scale, decimal point position, display resolution, digital filter strength, and translation correction. Level 0.2 measurement accuracy. It can support up to 6 channels of signal measurement. It can be used as an analog data acquisition module in a computer monitoring system or PLC to provide analog data acquisition for the computer. It can also provide switching input or output to the host computer, and the host computer can perform switching operations through the instrument. . It has built-in calculation functions such as square root, multiplier, adder and subtractor, and can display and convert the calculation results into standard signal output or transmit them to the host computer. Built-in dry and wet bulb temperature measurement calculation function. Each circuit has independent upper and lower limit alarm functions, and its alarm output can be freely programmed, allowing multiple alarm signals to be output from the same module position. |

tower | 1 | |

| 3 | Flow detection display instrument |

Flow detection and display instrument: intelligent flow totalizer, pulse signal input, 4~20mA/1~5V square root signal input, with RS485 communication interface. It can record and accumulate calculations of fluid indicators. And can carry out batch control. The m*n features of the instrument are as follows: programmable input specifications and programmable flow input signal. It can be installed with various common modules and rich programmable functions of AI series instruments, which can realize the upper and lower limit alarm functions of instantaneous flow, temperature and pressure, and has various functions such as transmission output, communication, 24V/12V voltage output and so on. It has an 8-digit accumulator and a 4-digit instantaneous measurement value display. It can select square root/no square root processing and set any range of small signal cut-off function. Accuracy: 0.5 level. Output: standard serial port, photoelectric isolation, RS485, RS422, RS232, fully isolated input and output, can provide 24V/30mA feed output for the transmitter. Instrument settings: You can set parameters such as instrument type, input range, display range, display mode, alarm type, and alarm limits. Alarm mode: Alarm control LED indication. Full range, non-polar. |

tower | 1 | |

| 4 | On-site concentration detection and display instrument |

Concentration detection and display instrument: intelligent display instrument, universal signal input, with 4~20mA transmission signal output, touch button. The performance parameters are as follows: 1. Input signal: standard thermocouple N, K, E, J, T, S, R, B, etc. 2. Standard thermal resistance PT100, CU50, CU100 3. DC current 0~10mA, 4~20mA input Impedance ≤250Ω 4. DC voltage 0~5V, 1~5V 5. Input impedance ≧250kΩ. Level 0.3 measurement accuracy. D610. |

tower | 3 | |

| 5 | Absorption and desorption liquid flow controller |

Absorption and desorption liquid flow controller: intelligent adjustment controller with touch buttons, universal signal input, 4~20mA control signal output, and RS485 communication interface. The performance parameters are as follows: 1. Input signal: standard thermocouple N, K, E, J, T, S, R, B, etc. 2. Standard thermal resistance PT100, CU50, CU100; 3. DC current 0~10mA, 4~20mA 4. Input impedance ≤ 250Ω 5. DC voltage 0~5V, 1~5V 6. Input impedance ≥ 250kΩ 7. Display mode: PV display with 4 digits (0.56″ or 0.36″ LED red) measured value SV display with 4 digits Display (0.56″ or 0.36″ LED green) 8. Set value or control output value 9. Display range: -999 ~ 9999 (measured value, set value) 0.000 ~ 1.000 (control output value), accuracy: 0.1 level 10 .Signal: Analog control output 0~10mADC (load resistance ≤1000Ω)/4~20mADC (load resistance ≤750Ω) 11. Output: Standard serial port, photoelectric isolation, RS485, input and output are completely isolated 12. Instrument settings: The instrument can be configured Type, input range, display range, display mode, alarm type, alarm limit and other parameters are set. 13. Alarm mode: alarm control, LED indication, full range, non-polar. |

tower | 2 | |

| 6 | Relay output instrument: | Switching relay output, 6 channels. | tower | 1 | |

| 7 | Flash alarm: | 8-channel alarm signal input with sound and light indication. | tower | 1 | |

| (Four) | Absorption and desorption tr*ning device actuator: | set | 1 | ||

| 1 | The electromagnetic valve | Solenoid valve: 12W31-15, DN15, normally closed. | tower | 1 | |

| 2 | Frequency converter | Mitsubishi inverter, specifications: single-phase 220V; 0.4KW (0-50)Hz. Mitsubishi Japan | tower | 2 | |

| (five) | Absorption and desorption tr*ning device, intelligent instrument, electrical console and computer control console: | ||||

| 1 | Smart instrument electrical console | Intelligent instrument and electrical console: Approximately 1650X700X1400 steel spray-p*nted piano-type structure on-site instrument and electrical console (including instruments, embedded microcomputer positions and switch positions, and cont*ns a DCS access port). The internal leakage protection *r switch and current leakage protector fully consider the personal safety protection; at the same time, each group of strong current output has a knob switch control to ensure the safety of the equipment and convenient operation and control; it is equipped with split-phase indicator light, switching power supply, contact relays, solid state relays, self-locking switches, plastic copper wires, rubber sheathed wires, shielded wires, wire troughs, etc. | tower | 1 | |

| (six) | Absorption and desorption tr*ning device on-site intelligent instrument computer control system: | ||||

| 1 | Operator station upper monitoring computer | Brand computer, configuration: dual-core 3.0G, memory: 4G, 512G hard drive, mouse, keyboard, monitor: 21.5-inch high-definition LCD monitor, genuine Windows 10 operating system. | tower | 1 | |

| 2 | Communication network converter |

Communication network converter: RS485/232. It can convert the data transmission and data reception signals of the RS232C serial port into a two-line balanced half-duplex RS485 signal; no external AC or DC power supply is required, and the power can be obt*ned directly from the data transmission signal, request transmission or data terminal in the RS232 port. , and also adds the function of automatic control of sending data. Interface: Compatible with EIA/TIA RS-232C and RS-485 standards; transmission rate: 115.2KBPS at 300M, 19.3KBPS at 1200M, 9600BPS at 2400M, and 2400BPS at 3 kilometers. Usage environment: -25℃ to 70℃, relative humidity 5% to 95%. |

indivual | 1 | |

| (seven) | Absorption and desorption tr*ning device intelligent instrument upper monitoring software: | set | 1 | ||

| 1 | Industrial control configuration software |

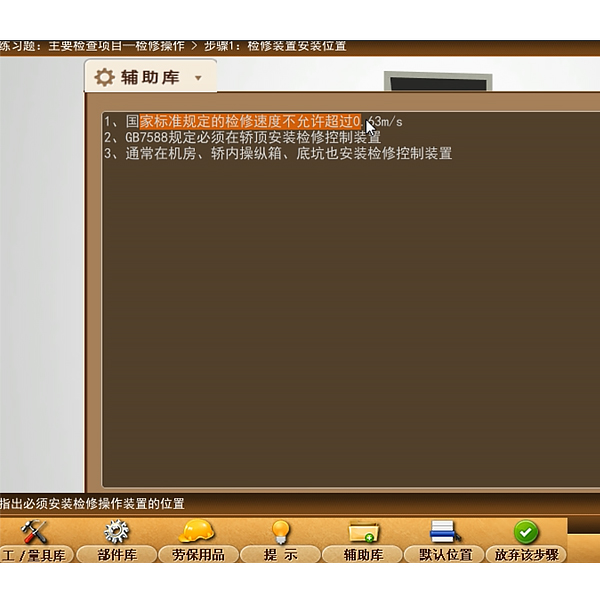

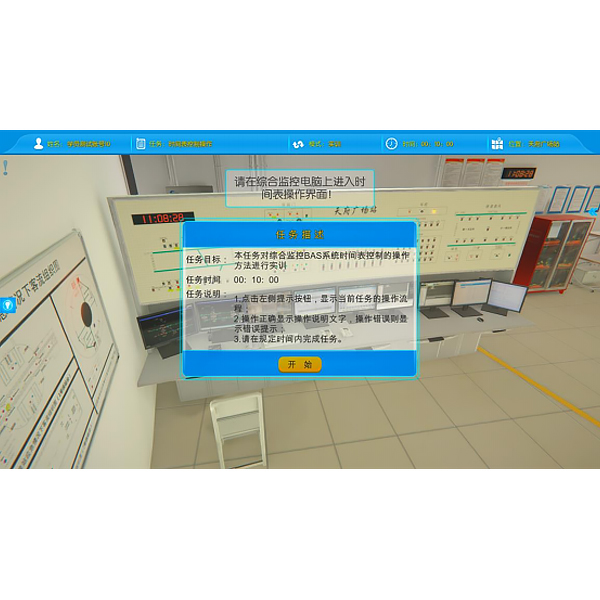

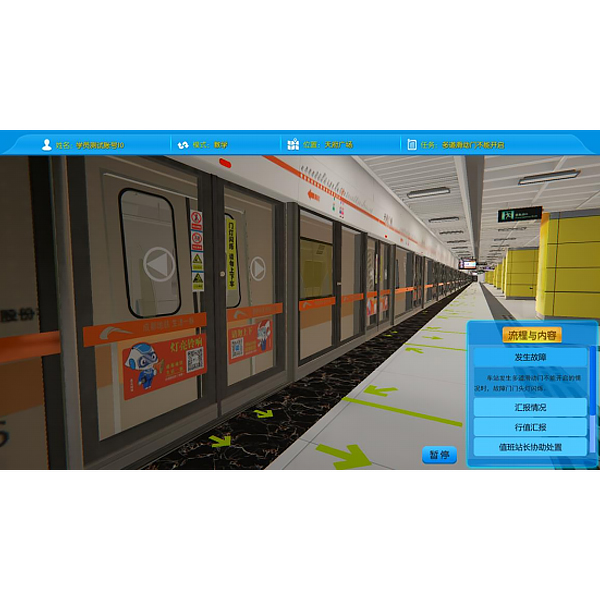

Industrial control configuration software platform software. MCGS6.2 configuration software. Mechanical tr*ning safety education virtual simulation software: This software is developed based on unity3d. The software adopts the form of three-dimensional roaming. Movement can be controlled by the keyboard and the lens direction can be controlled by the mouse. It is equipped with mechanical safety distance experiments, mechanical safety protection device experiments, and mechanical safety protection design. For the basic assessment, when the experiment is in progress, the three-dimensional roaming screen uses arrows and footprints to prompt the user to move to the experimental location. The circle around the mechanical object shows the working radius. The experimental process is accompanied by a dialog box reminder of the three-dimensional robot. A. The content of the mechanical safety distance experiment includes the safety distance experiment to prevent upper and lower limbs from touching the danger zone (divided into two fence heights and opening sizes). After selecting to enter, GB23821-2009 "Mechanical Safety to Prevent Upper and Lower Limbs from Touching the Danger Zone" pops up in front of the camera. "Safe Distance" requirements, error demonstration: The experimental process is that after the human body enters the working radius of the mechanical object and is injured, the red screen and voice prompts that the human body has received mechanical damage, and returns to the original position and conducts the next experiment. The last step is the correct approach. B. Mechanical safety protection device experiments are divided into safety interlock switches, safety light curt*ns, safety mats, safety laser scanners and other protection device experiments. Optional categories (safety input, safety control, safety output, others), manufacturers, products List (safety interlock switch, safety light curt*n, safety mat, safety laser scanner, safety controller, safety relay, safety guardr*l). There is a blue flashing frame reminder at the installation location. Experimental process: select the safety guardr*l and install it, select the safety interlock switch (or select the safety light curt*n, safety mat, safety laser scanner) and install it, select the safety controller and install it in the electrical control box , select the safety relay and install it in the electrical control box, click the start button on the electrical control box. If you enter a dangerous area, the system will sound an alarm and the mechanical object will stop working. Select the reset button on the electrical control box to stop. C. The basic assessment of mechanical safety protection design requires the completion of the installation of the mechanical safety system, and the correct installation of safety guardr*ls, safety interlock switches, safety light curt*ns, safety mats, safety laser scanners, safety controllers, safety relays, 24V power supplies, signal lights and Emergency stop button. The assessment is divided into ten assessment points. Some assessment points have 3 options, which are freely chosen by the students. After selecting the final 10 assessment points, submit for confirmation, and the system will automatically obt*n the total score and the score of each assessment point. . D. The software must be on the same platform as a whole and must not be displayed as separate resources. At the same time, the VR installation package of this software is provided to customers to facilitate users to expand into VR experiments. VR equipment and software installation and debugging are not required. |

set | 1 | |

| 2 | Upper level monitoring software | Upper-level monitoring software (using industrial control configuration software as the platform software). Matched with equipment. | set | 1 | |

| 3 | Experiment instructions | Experimental instructions. Matched with equipment. | set | 1 | |

Wechat scan code follow us

Wechat scan code follow us

24-hour hotline+86 18916464525

Phone18916464525

ADD:Factory 414, District A, No. 6, Chongnan Road, Songjiang Science and Technology Park, Shanghai ICP: Sitemap